Aging and predictions of Li-ion batteries for vehicle applications

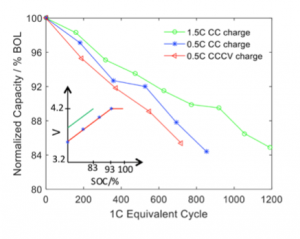

The figure shows that aging varies with the mode charging. In this case NMC/C commercial cylindrical cells charged at high rate (1.5C) but only to 83% Stage of Charge (SOC) were shown to degrade slower than cells charged at lower rate (0.5 C) but to higher SOC. In fact the cells charged to 100 % was the cells degrading fastest. This implies that it is not the rate of charging that probably is the most critical for aging but rather the time at high SOC that ages the cells. However, same type of aging was observed for all cases. Loss of available lithium ions for cycling was the dominating effect of aging, followed by loss of active material in the positive electrode

Background

Aims

Approaches

Keywords

Project leaders

Other project members

Funding agency